- Location of home is Iowa City

- 1000 sq ft, 2 bedroom, and no basement

- Found R-values based on good insulation, windows, and doors

- Degree Days

- Heating degree days = 7228

- Cooling degree days = 1270

- Manual J standard & Smith (1999) used for heating and cooling loads

- Total heat load = 32,000 Btu/h

- Total cooloing load = 16,650 Btu/h

Energy System for the home

- Geothermal heating and cooling system was chosen

- Iowa City not sufficient for solar irradiation

- Not enough wind to justify wind power

Heating

- Loop size & configuration

- Vertical loop due to lack of land space

- Higher up front cost but better longterm efficiency

- less disruption of landscape (can plant more trees etc.)

- 3/4" outer diameter Polyethyline pipe

- Required pipe length of loop = 730 ft

- Used 800 ft. (oversized for better performance)

- 3 bores at 250 ft deep spaced apart 20 ft

- Would require approx 50 ft^2 of surface space (Far less than horizontal)

- $200 more for the extra pipe but well worth it.

Formula used for sizing ground loop:

*Takes worst case scenario into consideration. Uses January temps & run hours

- Pump for fluid loop

- Dayton 5PXX4

- 1/8 hp

- 3/4" inlets and outlets

- 11 gallons per minute

- 15 ft of head loss

- Heat Pump

- 31,000 btu/h heating

- 1.6 Ton cooling

- Duct Work

- Max tons of AC = 2 tons

- 800 total cfm of air flow

- supply

- 2- 7" round for living room (300 cfm)

- 5- 6" round for the rest of the house

- 2-master bedroom

- 1-kitchen, bathroom, spare bedroom

- return

- 16" X 25" return opening for filter grate

- rule of thumb for return is 2 cfm per sq in of return grille size

- 8" X 10" - spare bedroom

- 8" X 12" - master bedroom

- 10" X 25" - living room

- none in kitchen or bathroom (odors)

- Economic Comparison

Annual return for the geothermal system is $960 per year

Capital cost to install natural gas furnace and conventional AC = $7500

(This includes the equipment, labor, and duct work parts & labor)

(Based on two estimates given by Family Heating and Cooling and Mr HVAC, both of the Quad Cities)

Geothermal Equipment:

Water Furnace by Envision

- Higher efficiency

- Less noise during operation

- Dual Stage system

- Higher upfront cost

- Uses less energy

- Model 026

- Heating-31,000 btu/h COP=5.5

- Cooling - 19,500 EER =18.6

Capital Cost

- Pipe = $2400

- Duct Work = $1000

- Equipment = $8000

- Labor = $2600

- Total Cost = $14,000 - 30% rebate = $9800

(Matched up with ballpark estimate for Iowa City on Geothermal sizing & cost ballpark figures)

(Figures based on cost estimate done by Family Heating and Cooling and Matt Burke)

Simple payback time

$9800 / ($1560-$600) = 10.2 year payback period

- The payback time did not meet the magic number of 7 years.

- Going with the conventional equipment would be more cost effective up front.

- Recommend considering geothermal if:

- prospective owner feels strong about conserving energy

- manufacture estimations are trusted

- 20 year life of equipment

- 50 year life of loop

- Possibility of 10 years of use after system has paid for itself

Description of LEED

LEED, or Leadership in Energy and Environmental Design, is an internationally-recognized green building certification system. Developed by the U.S. Green Building Council (USGBC) in March 2000, LEED provides building owners and operators with a framework for identifying and implementing practical and measurable green building design, construction, operations and maintenance solutions.

Details of LEED Certification

· Home Size Adjustment

o Apx. 1000 sq ft – two bedroom ( -9 pts)

· Innovation and Design

o 1.1 – Preliminary Rating – need 66 pts for GOLD certification

o 1.2 – Integrated Project Team ( 1 pt )

o 1.3 – Professional Credentialed with Respect to LEED for Homes ( 1 pt )

o 1.4 – Workshop for Green Strategies ( 1 pt )

o 2.1 – Durability Planning

o 2.2 – Durability Management

o 2.3 – Third-Party Durability Management Verification ( 3 pt )

· Location and Linkages

o 2 – Follow the rules of Site Selection ( 2 pt )

o 3.1 – 25% of perimeter borders previously developed land ( 1 pt )

o 4 – within ½ mile of water and service lines ( 1 pt )

o 5.1 – within ½ mile of bus stop (30 or more stops per day) ( 1 pt )

o 6 – within ½ mile of publicly accessible open space ( 1 pt )

· Sustainable Sites

o 1.1 – design and plan appropriate erosion control measures

o 1.2 – Minimize Disturbed Area of Site ( 1 pt )

o 2.1 – no invasive plants

o 2.3 – no conventional turf ( 3 pt )

o 2.4 – make 50% of plants drought tolerant ( 1 pt )

o 4.2 – plant 1 tree for every 500 sq ft of disturbed lot area ( 1 pt )

o 5 – meet all pest control alternatives ( 2 pt )

o 6 – build house on a 1/7 acre lot ( 2 pt )

· Water Efficiency

o 3.2 – average flow rate for lavatory faucets ≤ 1.5 gpm , average flow rate of showers ≤ 1.75 gpm , average flow rate of toilets ≤ 1.1 gpf ( 6 pt )

· Energy and Atmosphere

o 2.1 – 2.2 – install insulation that exceeds R-value requirements ( 2 pt )

o 3.1 – 3.2 – greatly reduce air leakage ( 2 pt )

o 4.3 – install exceptional windows , U-factor ≤ .28 ( 3 pt )

o 5.3 – install heat pump/duct system with minimal distribution losses ( 3 pt )

o 6.3 – install very efficient geothermal system ( 4 pt )

o 8.3 – install ENERGY STAR advanced lighting package ( 3 pt )

o 9 – install ENERGY STAR refrigerator, ceiling fans, dishwasher and clothes dryer ( 2 pt )

· Materials and Resources

o 1.1 – limit the overall estimated waste factor limit to 10% or less

o 1.2 – detailed framing plans for special architectural details ( 1 pt )

o 1.3 – create a detailed cut list and lumber order ( 1 pt )

o 3.1 – 3.2 – generate 2.5 lbs or less of waste per sq ft of floor area and divert 25% or more of the total waste from landfills and incinerators ( 3 pt )

· Indoor Environmental Quality

o 2.1 – meet combustion venting measures

o 2.2 – no fire place/wood stove ( 2 pt )

o 5.1 – exhaust systems in bathrooms and kitchens

o 5.2 – occupy sensor in every bathroom ( 1 pt )

o 5.3 – third party performance test for exhaust flow rate ( 1 pt )

o 6.1 – perform design calculations for system

o 6.2 – every room has adequate return air flow ( 1 pt )

o 6.3 – third party performance test ( 1 pt )

o 7.3 – install best air filters MERV ≥ 13 ( 2 pt )

o 8.1 – seal all permanent ducts and vents during construction ( 1 pt )

o 8.2 – install permanent walk-off grates (4 ft long) and a shoe removal and storage system ( 2 pt )

o 8.3 – preoccupancy flush ( 1 pt )

o 9.1 – 9.2 – protect EVERYTHING from Radon ( 1 pt )

o 10.1 – 10.4 – no HVAC in the garage + detached garage ( 3 pt )

· Awareness and Education

o 1.1 – 1.2 – two hours of training for the occupants ( 1 pt )

o 1.3 – promote general public awareness about LEED ( 1 pt )

· TOTAL = 70 pts

Price Breakdown of LEED

Category | Price | Payback Time |

Innovation and Design | ||

Green Rater | ($500) | |

Mech. Engineer | ($500) | |

Civil Engineer | ($500) | |

Extra Costs for Architect/Builders | ($1,000) | |

Sustainable Sites | ||

Erosion Control Materials | ($200) | |

Buffalo Grass (seed) | ($235) | < month |

Trees | ($250) | |

Termite Control | ($100) | |

1/7 acre opposed to 1/4 acre | $10,000 | |

Energy and Atmosphere | ||

Insulation + air leakage reduction | ($2,000) | |

Excellent Windows | ($400) | |

Geothermal System | ($14,000) | 10.2 years |

High Efficiency Forced Air System | ($6,000) | |

30% rebate | $4,200 | |

ENERGY STAR advanced lighting package | ($1,000) | 3 years |

ENERGY STAR appliances | ($1,000) | 5 years |

Materials and Resources | ||

House + garage (reduction in lumber) | $5,000 | |

Indoor Environmental Quality | ||

CO monitor | ($25) | |

Exhaust Systems | ($500) | |

Occupancy Sensors | ($75) | |

Air Filters (MERV > 13) | ($50) | |

Perminant walk-off grates | ($500) | |

Preoccupancy Flush | ($500) | |

Tax Credits and Deductions | $1,500 | $1.50 per sq ft |

Total | ($8,635) |

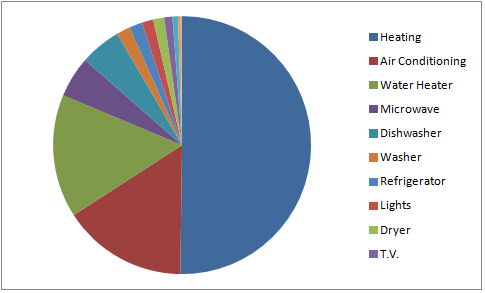

CO2 Footprint Reduction from LEED

(Generated using EPA Household Emissions Calculator - 2 people)

Before LEED

Vehicles - 24886 lbs CO2 per year

Home - 34855 lbs

Waste - 2042 lbs

Total = 62383 lbs

Changes Made

- no natural gas

- 60% reduction in electricity (ENERGY STAR)

- recylcing

- drop the mileage of each car by 40 miles/week

- cut oil consumption in half

- cut propane consumption in half

After LEED

Vehicles - 21238 lbs

Home - 12478 lbs

Waste - 1149 lbs

Total = 34865 lbs

http://www.epa.gov/climatechange/emissions/ind_calculator.html

·