Energy Systems Design

This blog features information pertaining to topics covered in our Energy System Design class at the University of Iowa for the Fall semester of 2011. It is a collaboration between Matt Burke and Matt Mercer and will be focused around the theme of energy sustainability.

Monday, April 23, 2012

Monday, December 12, 2011

Final Project Presentation

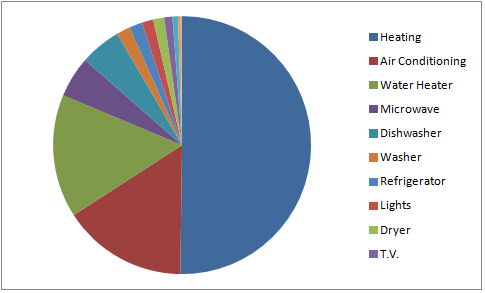

Energy Analysis for the home

Energy System for the home

Price Breakdown of LEED

CO2 Footprint Reduction from LEED

(Generated using EPA Household Emissions Calculator - 2 people)

Before LEED

Vehicles - 24886 lbs CO2 per year

Home - 34855 lbs

Waste - 2042 lbs

Total = 62383 lbs

Changes Made

- no natural gas

- 60% reduction in electricity (ENERGY STAR)

- recylcing

- drop the mileage of each car by 40 miles/week

- cut oil consumption in half

- cut propane consumption in half

After LEED

Vehicles - 21238 lbs

Home - 12478 lbs

Waste - 1149 lbs

Total = 34865 lbs

http://www.epa.gov/climatechange/emissions/ind_calculator.html

- Location of home is Iowa City

- 1000 sq ft, 2 bedroom, and no basement

- Found R-values based on good insulation, windows, and doors

- Degree Days

- Heating degree days = 7228

- Cooling degree days = 1270

- Manual J standard & Smith (1999) used for heating and cooling loads

- Total heat load = 32,000 Btu/h

- Total cooloing load = 16,650 Btu/h

Energy System for the home

- Geothermal heating and cooling system was chosen

- Iowa City not sufficient for solar irradiation

- Not enough wind to justify wind power

Heating

- Loop size & configuration

- Vertical loop due to lack of land space

- Higher up front cost but better longterm efficiency

- less disruption of landscape (can plant more trees etc.)

- 3/4" outer diameter Polyethyline pipe

- Required pipe length of loop = 730 ft

- Used 800 ft. (oversized for better performance)

- 3 bores at 250 ft deep spaced apart 20 ft

- Would require approx 50 ft^2 of surface space (Far less than horizontal)

- $200 more for the extra pipe but well worth it.

Formula used for sizing ground loop:

*Takes worst case scenario into consideration. Uses January temps & run hours

- Pump for fluid loop

- Dayton 5PXX4

- 1/8 hp

- 3/4" inlets and outlets

- 11 gallons per minute

- 15 ft of head loss

- Heat Pump

- 31,000 btu/h heating

- 1.6 Ton cooling

- Duct Work

- Max tons of AC = 2 tons

- 800 total cfm of air flow

- supply

- 2- 7" round for living room (300 cfm)

- 5- 6" round for the rest of the house

- 2-master bedroom

- 1-kitchen, bathroom, spare bedroom

- return

- 16" X 25" return opening for filter grate

- rule of thumb for return is 2 cfm per sq in of return grille size

- 8" X 10" - spare bedroom

- 8" X 12" - master bedroom

- 10" X 25" - living room

- none in kitchen or bathroom (odors)

- Economic Comparison

Annual return for the geothermal system is $960 per year

Capital cost to install natural gas furnace and conventional AC = $7500

(This includes the equipment, labor, and duct work parts & labor)

(Based on two estimates given by Family Heating and Cooling and Mr HVAC, both of the Quad Cities)

Geothermal Equipment:

Water Furnace by Envision

- Higher efficiency

- Less noise during operation

- Dual Stage system

- Higher upfront cost

- Uses less energy

- Model 026

- Heating-31,000 btu/h COP=5.5

- Cooling - 19,500 EER =18.6

Capital Cost

- Pipe = $2400

- Duct Work = $1000

- Equipment = $8000

- Labor = $2600

- Total Cost = $14,000 - 30% rebate = $9800

(Matched up with ballpark estimate for Iowa City on Geothermal sizing & cost ballpark figures)

(Figures based on cost estimate done by Family Heating and Cooling and Matt Burke)

Simple payback time

$9800 / ($1560-$600) = 10.2 year payback period

- The payback time did not meet the magic number of 7 years.

- Going with the conventional equipment would be more cost effective up front.

- Recommend considering geothermal if:

- prospective owner feels strong about conserving energy

- manufacture estimations are trusted

- 20 year life of equipment

- 50 year life of loop

- Possibility of 10 years of use after system has paid for itself

Description of LEED

LEED, or Leadership in Energy and Environmental Design, is an internationally-recognized green building certification system. Developed by the U.S. Green Building Council (USGBC) in March 2000, LEED provides building owners and operators with a framework for identifying and implementing practical and measurable green building design, construction, operations and maintenance solutions.

Details of LEED Certification

· Home Size Adjustment

o Apx. 1000 sq ft – two bedroom ( -9 pts)

· Innovation and Design

o 1.1 – Preliminary Rating – need 66 pts for GOLD certification

o 1.2 – Integrated Project Team ( 1 pt )

o 1.3 – Professional Credentialed with Respect to LEED for Homes ( 1 pt )

o 1.4 – Workshop for Green Strategies ( 1 pt )

o 2.1 – Durability Planning

o 2.2 – Durability Management

o 2.3 – Third-Party Durability Management Verification ( 3 pt )

· Location and Linkages

o 2 – Follow the rules of Site Selection ( 2 pt )

o 3.1 – 25% of perimeter borders previously developed land ( 1 pt )

o 4 – within ½ mile of water and service lines ( 1 pt )

o 5.1 – within ½ mile of bus stop (30 or more stops per day) ( 1 pt )

o 6 – within ½ mile of publicly accessible open space ( 1 pt )

· Sustainable Sites

o 1.1 – design and plan appropriate erosion control measures

o 1.2 – Minimize Disturbed Area of Site ( 1 pt )

o 2.1 – no invasive plants

o 2.3 – no conventional turf ( 3 pt )

o 2.4 – make 50% of plants drought tolerant ( 1 pt )

o 4.2 – plant 1 tree for every 500 sq ft of disturbed lot area ( 1 pt )

o 5 – meet all pest control alternatives ( 2 pt )

o 6 – build house on a 1/7 acre lot ( 2 pt )

· Water Efficiency

o 3.2 – average flow rate for lavatory faucets ≤ 1.5 gpm , average flow rate of showers ≤ 1.75 gpm , average flow rate of toilets ≤ 1.1 gpf ( 6 pt )

· Energy and Atmosphere

o 2.1 – 2.2 – install insulation that exceeds R-value requirements ( 2 pt )

o 3.1 – 3.2 – greatly reduce air leakage ( 2 pt )

o 4.3 – install exceptional windows , U-factor ≤ .28 ( 3 pt )

o 5.3 – install heat pump/duct system with minimal distribution losses ( 3 pt )

o 6.3 – install very efficient geothermal system ( 4 pt )

o 8.3 – install ENERGY STAR advanced lighting package ( 3 pt )

o 9 – install ENERGY STAR refrigerator, ceiling fans, dishwasher and clothes dryer ( 2 pt )

· Materials and Resources

o 1.1 – limit the overall estimated waste factor limit to 10% or less

o 1.2 – detailed framing plans for special architectural details ( 1 pt )

o 1.3 – create a detailed cut list and lumber order ( 1 pt )

o 3.1 – 3.2 – generate 2.5 lbs or less of waste per sq ft of floor area and divert 25% or more of the total waste from landfills and incinerators ( 3 pt )

· Indoor Environmental Quality

o 2.1 – meet combustion venting measures

o 2.2 – no fire place/wood stove ( 2 pt )

o 5.1 – exhaust systems in bathrooms and kitchens

o 5.2 – occupy sensor in every bathroom ( 1 pt )

o 5.3 – third party performance test for exhaust flow rate ( 1 pt )

o 6.1 – perform design calculations for system

o 6.2 – every room has adequate return air flow ( 1 pt )

o 6.3 – third party performance test ( 1 pt )

o 7.3 – install best air filters MERV ≥ 13 ( 2 pt )

o 8.1 – seal all permanent ducts and vents during construction ( 1 pt )

o 8.2 – install permanent walk-off grates (4 ft long) and a shoe removal and storage system ( 2 pt )

o 8.3 – preoccupancy flush ( 1 pt )

o 9.1 – 9.2 – protect EVERYTHING from Radon ( 1 pt )

o 10.1 – 10.4 – no HVAC in the garage + detached garage ( 3 pt )

· Awareness and Education

o 1.1 – 1.2 – two hours of training for the occupants ( 1 pt )

o 1.3 – promote general public awareness about LEED ( 1 pt )

· TOTAL = 70 pts

Price Breakdown of LEED

Category | Price | Payback Time |

Innovation and Design | ||

Green Rater | ($500) | |

Mech. Engineer | ($500) | |

Civil Engineer | ($500) | |

Extra Costs for Architect/Builders | ($1,000) | |

Sustainable Sites | ||

Erosion Control Materials | ($200) | |

Buffalo Grass (seed) | ($235) | < month |

Trees | ($250) | |

Termite Control | ($100) | |

1/7 acre opposed to 1/4 acre | $10,000 | |

Energy and Atmosphere | ||

Insulation + air leakage reduction | ($2,000) | |

Excellent Windows | ($400) | |

Geothermal System | ($14,000) | 10.2 years |

High Efficiency Forced Air System | ($6,000) | |

30% rebate | $4,200 | |

ENERGY STAR advanced lighting package | ($1,000) | 3 years |

ENERGY STAR appliances | ($1,000) | 5 years |

Materials and Resources | ||

House + garage (reduction in lumber) | $5,000 | |

Indoor Environmental Quality | ||

CO monitor | ($25) | |

Exhaust Systems | ($500) | |

Occupancy Sensors | ($75) | |

Air Filters (MERV > 13) | ($50) | |

Perminant walk-off grates | ($500) | |

Preoccupancy Flush | ($500) | |

Tax Credits and Deductions | $1,500 | $1.50 per sq ft |

Total | ($8,635) |

CO2 Footprint Reduction from LEED

(Generated using EPA Household Emissions Calculator - 2 people)

Before LEED

Vehicles - 24886 lbs CO2 per year

Home - 34855 lbs

Waste - 2042 lbs

Total = 62383 lbs

Changes Made

- no natural gas

- 60% reduction in electricity (ENERGY STAR)

- recylcing

- drop the mileage of each car by 40 miles/week

- cut oil consumption in half

- cut propane consumption in half

After LEED

Vehicles - 21238 lbs

Home - 12478 lbs

Waste - 1149 lbs

Total = 34865 lbs

http://www.epa.gov/climatechange/emissions/ind_calculator.html

·

Tuesday, November 1, 2011

Part 2-4 Heating and Cooling Energy needs for the home

Qheat = (UA + mdot * Cpa) * HDD

Qcool, sensible = (UA + mdot * Cpa) * CDD

Qcool, latent = mdot * hfg * SUM(wb-wo)deltaT

= 67470199 Btu

Qcool, sensible = (UA + mdot * Cpa) * CDD

= [(146.76Btu/F*hr)+(211.8 lb/hr)*(0.2441Btu/lb*F)]*1270*day(24hr)

=6049072 Btu

Qcool, latent = mdot * hfg * SUM(wb-wo)deltaT

= (211.8 lb/hr)(970.34 Btu/lb)(22.48 hr) = 4620045 Btu

Qcool, sensible = (UA + mdot * Cpa) * CDD

Qcool, latent = mdot * hfg * SUM(wb-wo)deltaT

Cp=0.2441 Btu/lb

mdot=211.8 lb/hr

hfg=970.34 Btu/lb

Qheat = (UA + mdot * Cpa) * HDD

=[(337.24Btu/F*hr)+(211.8 lb/hr)*(0.2441Btu/lb*F)] * 7228F*day (24hr)= 67470199 Btu

Qcool, sensible = (UA + mdot * Cpa) * CDD

= [(146.76Btu/F*hr)+(211.8 lb/hr)*(0.2441Btu/lb*F)]*1270*day(24hr)

=6049072 Btu

Qcool, latent = mdot * hfg * SUM(wb-wo)deltaT

= (211.8 lb/hr)(970.34 Btu/lb)(22.48 hr) = 4620045 Btu

Part 2-3 Ventilation Rate of the Home

Assuming standard air exchange for homes, the ventilation rate was calculated as follows:

Desired air exchange rate = 0.35

8 ft ceilings

Ventilation rate = Volume*air exchange rate = (1000ft*8ft)(0.35/hr)(1hr/60min) = 46.67 cfm

or Q=mdot/density of air = (3.53 lb/min)/(0.0757lb/ft^3) @ 65 degrees F = 46.63 cfm

Desired air exchange rate = 0.35

8 ft ceilings

Ventilation rate = Volume*air exchange rate = (1000ft*8ft)(0.35/hr)(1hr/60min) = 46.67 cfm

or Q=mdot/density of air = (3.53 lb/min)/(0.0757lb/ft^3) @ 65 degrees F = 46.63 cfm

Part 2-2 Determine the heating and cooling degree days for a typical year

The heating degree days in Iowa City from 10/1/2010-09/1/2011 are shown below

The cooling degree days in Iowa City from 10/1/2010-09/1/2011 are shown below

Total heating degree days in a year in Iowa City = 7228

Totla cooling degree days in a year in Iowa City = 1270

Subscribe to:

Comments (Atom)